Show table of content Hide table of content

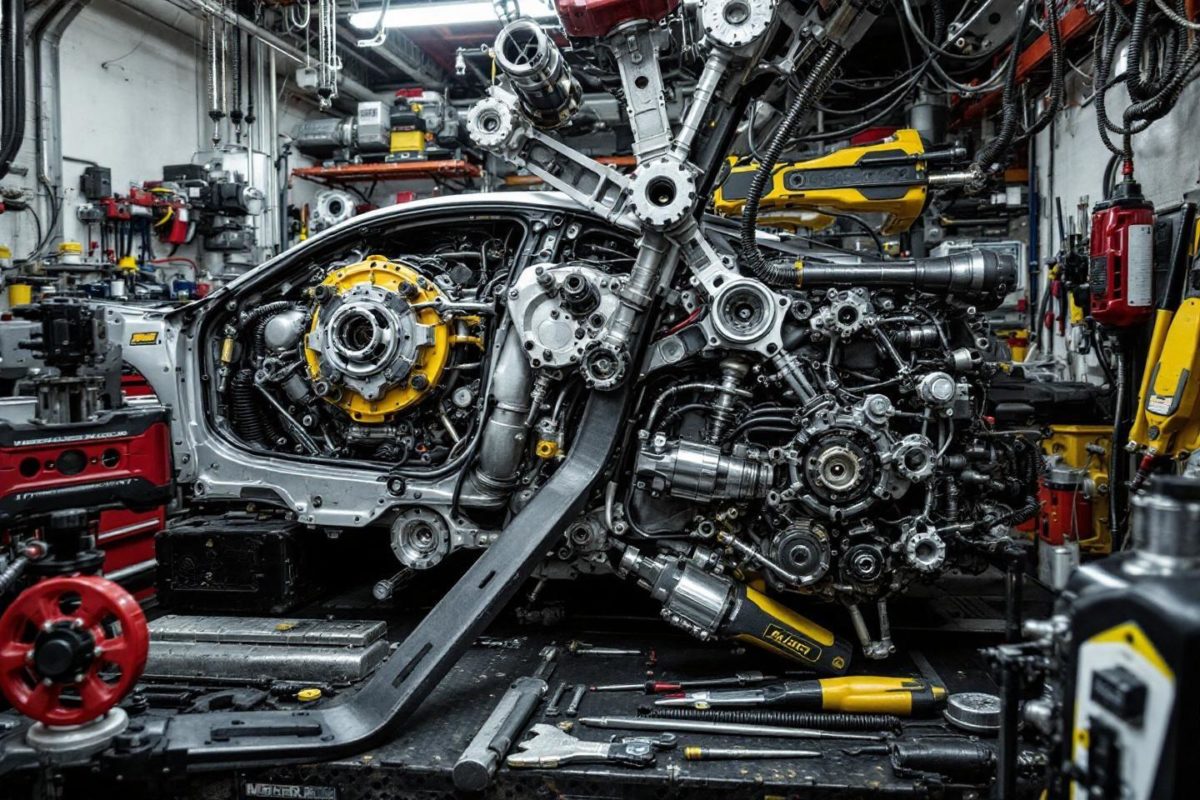

A universal suicide tilt hood kit represents a sophisticated automotive modification that allows complete hood removal without permanent alterations to the vehicle. This innovative system transforms how enthusiasts access engine compartments during maintenance, shows, or performance modifications. Unlike traditional hood mechanisms, suicide tilt systems enable the hood to open forward and completely detach from the vehicle frame.

The terminology “suicide” refers to the forward-opening direction, contrasting with conventional rear-hinged hoods. This design choice offers unprecedented access to engine bays while maintaining the original hood’s aesthetic appeal. Professional mechanics and car enthusiasts frequently choose these systems for their versatility and practical advantages in automotive applications.

Understanding the basic mechanics behind suicide tilt hood systems

The fundamental operation principle relies on a specialized hinge mechanism that replaces factory hood hinges. These systems typically incorporate heavy-duty pivot points positioned at the front of the hood rather than the traditional rear mounting location. The primary components include reinforced hinge assemblies, support brackets, and safety mechanisms designed to handle the altered weight distribution.

RVThis near-military 4×4 powered by a 300-hp Mercedes six-cylinder engine is the only one capable of rivaling the legendary G-ClassMost universal kits feature adjustable mounting hardware that accommodates various vehicle makes and models. The system’s versatility stems from its modular design approach, allowing installation on different hood configurations without extensive modifications. Engineers design these kits with precise tolerances to ensure smooth operation and reliable performance under various conditions.

The weight distribution aspect requires careful consideration during installation. Forward-opening hoods experience different stress patterns compared to rear-hinged systems, necessitating robust support mechanisms. Counterbalance systems often integrate into the design to facilitate easy operation while preventing sudden hood movements that could cause damage or injury.

| Component | Function | Material |

|---|---|---|

| Pivot Hinge | Primary rotation point | Steel/Aluminum |

| Support Bracket | Weight distribution | Reinforced Steel |

| Safety Latch | Secure closure | Stainless Steel |

| Gas Strut | Assisted opening | Composite Materials |

Installation process and technical requirements for universal kits

Professional installation typically begins with complete hood removal and thorough inspection of mounting surfaces. The process requires precise measurements to ensure proper alignment and optimal functionality. Mounting point preparation involves drilling specific holes and reinforcing areas that will bear the modified load distribution.

The installation sequence follows a systematic approach to maintain structural integrity throughout the modification process. Technicians must verify compatibility between the universal kit components and the specific vehicle’s hood design. Dimensional accuracy becomes crucial during this phase, as improper alignment can lead to operational issues or potential safety hazards.

RVRetro Toyota Land Cruiser gets G-Class treatment for EuropeCritical installation steps include :

- Removing factory hinges and hardware

- Preparing mounting surfaces for new components

- Installing reinforcement brackets and pivot mechanisms

- Calibrating opening angles and safety systems

- Testing full operational range and security features

Quality universal kits provide detailed installation instructions and templates for precise hole placement. The modification process typically requires basic automotive tools and mechanical aptitude, though professional installation ensures optimal results and warranty coverage.

Safety features and operational advantages of tilt hood mechanisms

Modern suicide tilt hood kits incorporate multiple safety mechanisms to prevent accidents and ensure reliable operation. Primary safety features include positive locking mechanisms, emergency release systems, and wind-resistance design elements. These systems prevent inadvertent hood opening while driving and provide secure closure during vehicle operation.

The operational advantages extend beyond simple engine access improvement. Complete hood removal capability facilitates detailed engine work, photography, and show presentation without obstruction. Maintenance accessibility increases significantly when the entire hood assembly can be removed quickly and safely.

Professional racing applications particularly benefit from rapid hood removal capabilities during pit stops or technical inspections. The system’s design allows single-person operation in most configurations, reducing the manpower required for hood removal during competitive events or maintenance procedures.

RVTrue 4×4 capability at a B-SUV price — this off-roader at around $26,000 is exactly what we need, and everyone had forgotten about itWind load considerations receive special attention in quality kit designs. Engineers incorporate aerodynamic features and reinforcement elements to maintain stability during normal driving conditions. Structural integrity remains paramount throughout the design process, ensuring long-term reliability under various operating conditions.

Maximizing performance and longevity through proper maintenance

Regular maintenance ensures optimal performance and extends the operational lifespan of suicide tilt hood systems. Lubrication schedules for pivot points and moving components prevent premature wear and maintain smooth operation. Periodic inspections help identify potential issues before they develop into serious problems or safety concerns.

Weather protection measures become particularly important for forward-opening hood systems. Proper sealing prevents water intrusion and corrosion in critical mechanical components. Preventive maintenance protocols should address these environmental factors to ensure consistent performance across various climate conditions.

Component replacement schedules vary based on usage patterns and environmental exposure. High-use applications may require more frequent inspection and maintenance intervals compared to occasional show vehicle installations. Quality manufacturers provide specific maintenance guidelines and replacement part availability to support long-term system reliability.

RVAffordable 4×4 remains unbeatable under $30,000Performance optimization involves periodic adjustment of opening angles, latch engagement, and counterbalance systems. These adjustments compensate for normal wear patterns and maintain the precise operation characteristics that make suicide tilt hood kits valuable automotive modifications for enthusiasts and professionals alike.