Show table of content Hide table of content

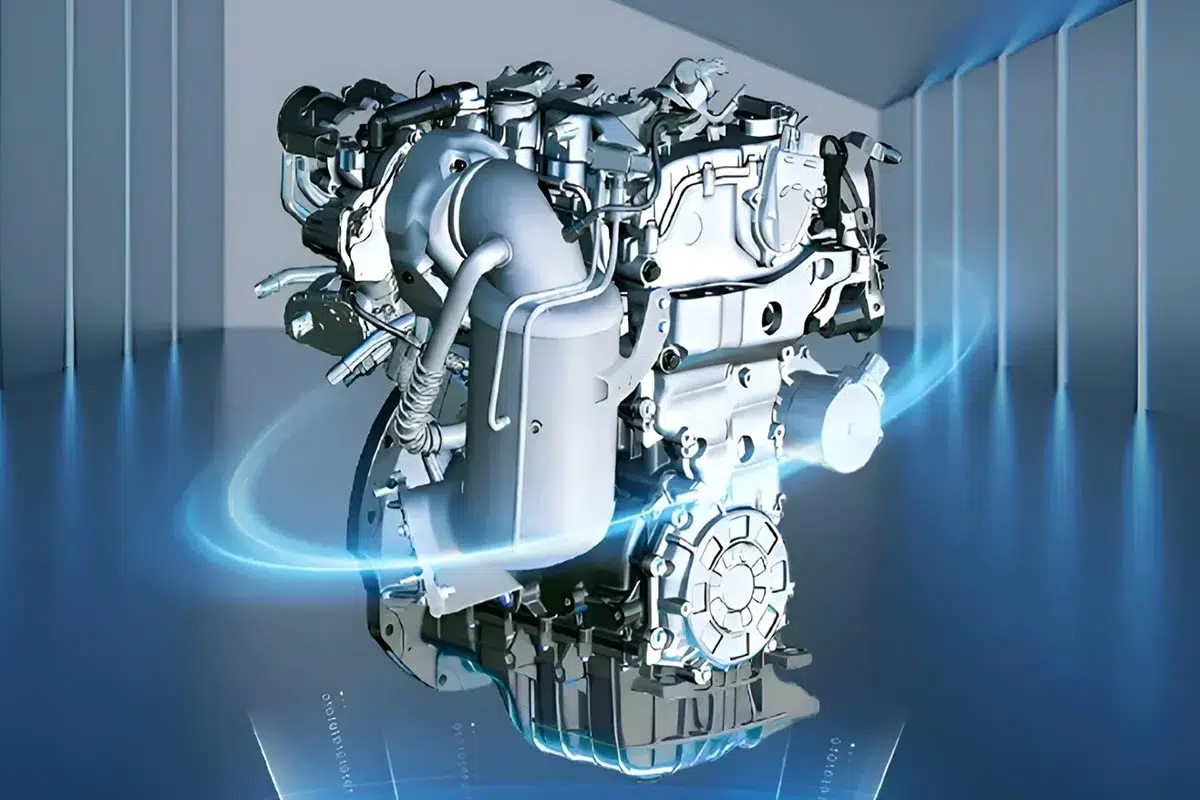

While the automotive industry seems entirely focused on electric mobility, Chinese automaker Dongfeng has just achieved a technological breakthrough that could reshape the debate around combustion engine efficiency. The manufacturer unveiled its Mach 1.5T powerplant, a turbocharged 1.5-liter gasoline engine specifically engineered for hybrid applications, boasting an independently certified thermal efficiency of 48.09%. This remarkable figure, validated by the China Automotive Technology and Research Center through its Energy Efficiency Star certification, represents a quantum leap in internal combustion technology that European manufacturers cannot afford to ignore.

Thermal efficiency measures how effectively an engine converts fuel energy into useful mechanical work rather than dissipating it as waste heat. Traditional hybrid engines typically achieve efficiency ratings between 40% and 41%, with only the most advanced recent designs pushing slightly beyond this threshold. Dongfeng’s achievement of 48.09% places this powerplant in an entirely different category, establishing a new benchmark for electrified vehicles that combines internal combustion with electric propulsion.

The technological innovations behind this performance are numerous and sophisticated. Engineers incorporated ultra-high compression ratios exceeding 15.5 :1, enabling more complete combustion of the fuel mixture. The system utilizes direct injection operating at 500 bar pressure, delivering fuel with unprecedented precision. Variable geometry turbocharging works in concert with optimized valve timing systems specifically calibrated for hybrid operation cycles. Additionally, extensive friction reduction measures throughout the mechanical components minimize parasitic losses that typically drain efficiency in conventional engines.

Electric VehicleIt looks like an off-roader, but it’s a hybrid SUV with a battery so powerful it can cover 310 miles without ever starting the gasoline engineThis engineering philosophy demonstrates that combustion technology continues to evolve, even as discussions about Europe’s reconsideration of the 2035 combustion engine ban intensify across the continent. The implications extend beyond mere technical curiosity—they challenge assumptions about the inevitable obsolescence of thermal engines.

| Engine specification | Dongfeng Mach 1.5T | Conventional hybrid engines |

|---|---|---|

| Thermal efficiency | 48.09% | 40-42% |

| Compression ratio | >15.5 :1 | 12-14 :1 |

| Injection pressure | 500 bar | 200-350 bar |

| Application | Hybrid dedicated | Multi-purpose |

Beyond impressive engineering specifications, this efficiency breakthrough translates into tangible benefits for everyday driving. Dongfeng claims the Mach 1.5T enables fuel consumption reductions that extend driving range by nearly 10% compared to previous-generation hybrid systems. This means fewer stops at fuel stations and lower operating costs over the vehicle’s lifetime, particularly valuable for non-plug-in hybrid architectures where the combustion engine remains the primary energy source.

The environmental advantages are equally significant. Higher thermal efficiency directly correlates with reduced CO₂ emissions, as less fuel must be burned to achieve equivalent power output. This optimization maintains effectiveness across varied driving conditions—urban stop-and-go traffic, steady highway cruising, and everything between. For markets where hybrid technology serves as a transitional solution rather than a permanent endpoint, such efficiency gains represent meaningful progress toward emission reduction targets.

The practical applications appear particularly suited to popular vehicle segments. SUVs and sedans equipped with this powerplant could deliver the performance consumers expect while dramatically reducing their environmental footprint. This balance between capability and responsibility addresses a persistent challenge in automotive design, where power and efficiency have traditionally existed in tension. While manufacturers like Porsche explore simulating manual gearbox feel in electric vehicles, Dongfeng demonstrates that combustion technology retains significant development potential.

Although Dongfeng has not formally announced which models will first receive this advanced powerplant, industry analysis suggests several likely candidates. The Dongfeng Aeolus Haoji, a compact SUV already available with electrified propulsion, represents a logical initial application. The forthcoming Nammi 6 crossover, designed around an optimized parallel hybrid architecture, could showcase the technology’s capabilities. Premium brand Voyah might deploy evolved versions combining high output with exceptional efficiency.

Electric VehicleHongqi SUV with solid-state battery charges in 5 minutesThe potential applications extend well beyond Dongfeng’s own product portfolio :

- Joint venture partnerships with global manufacturers like Honda, Nissan, or Stellantis could facilitate international deployment

- B-segment and C-segment vehicles in European and Asian markets could benefit from the technology with appropriate regulatory adaptations

- Emerging market applications where SUVs with combustion engines remain dominant could embrace hybrid efficiency

- Flexible platforms combining thermal, hybrid, and electric capabilities could standardize around this powerplant architecture

This achievement arrives at a particularly consequential moment for the automotive industry. As manufacturers like Toyota demonstrate hybrid SUV market dominance and even prepare electric versions of iconic models, Dongfeng’s engineering validates an alternative pathway. Rather than abandoning combustion technology entirely, strategic hybridization with ultra-efficient thermal engines may represent a viable transitional strategy.

European manufacturers face a strategic dilemma as they witness this technological advancement from China. The conventional narrative positioned electrification as inevitable and combustion engines as obsolete technology awaiting retirement. Dongfeng’s 48.09% efficiency challenges this simplistic framing, demonstrating that significant innovation potential remains within thermal engine development when properly directed toward hybrid applications.

The competitive implications are substantial. If Chinese manufacturers can offer hybrid vehicles with markedly superior efficiency compared to European counterparts, they gain considerable advantages in markets where pure electric infrastructure remains underdeveloped or consumer acceptance of battery electric vehicles progresses slowly. This technical leadership could translate into market share gains across Asia, Africa, and Latin America—regions representing enormous growth potential.

European manufacturers invested heavily in electric vehicle development, sometimes at the expense of continued combustion engine refinement. This strategic choice made sense within a regulatory framework pointing unambiguously toward electrification. However, as economic realities and infrastructure constraints complicate pure electric transitions, hybrid efficiency emerges as an increasingly relevant competitive dimension. Dongfeng’s achievement suggests Chinese manufacturers maintained broader technological portfolios, positioning themselves to capitalize on multiple potential futures.

Electric VehicleSubaru Solterra EV : faster than brand’s sports cars despite being SUVThe question facing European industry becomes whether to accelerate hybrid engine development to match Chinese efficiency standards or double down on pure electric strategies despite market uncertainties. This decision carries profound implications for industrial competitiveness, employment, and technological sovereignty across the continent.